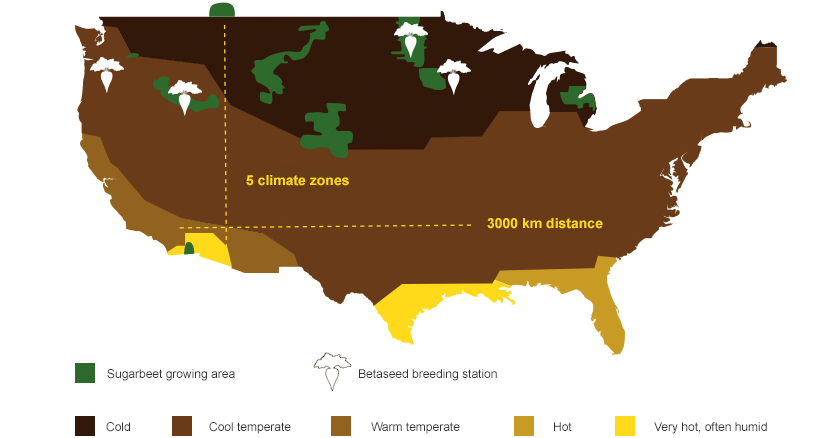

Sugarbeet acreage in the United States spans 11 growing regions. This means a broad spectrum of growing and climatic conditions, soil types, diseases and pests. Betaseed seeds have to handle all of the above.

Big differences in climatic conditions and soil types between regions

The climate in western areas has low precipitation levels, with cold nights and a long vegetation period. The majority of western acreage is irrigated. There is more rain in eastern states, meaning that irrigation is not absolutely necessary. The nights are warmer, and the vegetation period shorter.

In some regions, up to seven different disease tolerances are required for varieties that deliver maximum yield. Therefore, there are big differences in the genetic profiles needed in different regions. Farmers in western states use nematode-tolerant seeds by Betaseed, whereas Cercospora-tolerant seeds are needed in eastern areas. Due to extensive corn cultivation, Rhizoctonia tolerances are a standard feature in our range of varieties. Our experience in developing location-specific varieties for North America helps us produce healthy, high-yield varieties for the European market.

Seedlings of sugar beet with 48 rows seed drill in

North Dakota

Seedlings of sugar beet with 48 rows seed drill in

North Dakota

In the USA, approx. 4,500 farmers cultivate roughly 480,000 hectares of sugarbeet land, with each one farming 130 hectares of sugarbeet on average. The yield comes in at 70 t/ha and rises annually by approx. 0.6 t/ha. This results in a sugar yield of 12 t/ha.

The sugarbeet is processed in 23 sugar plants, operated by ten different companies – most of which are agricultural cooperatives. The volumes of sugarbeet for each company are based on the quotas set by the US government.

With field sizes of approx. 65 ha, the seeds are sown using planters with up to 48 rows and at sowing speeds of up to 10 km/h. Precision farming technologies such as GPS-assisted guidance systems and sensor-assisted crop management are already widely established, although European self-propelled harvesting equipment is less common in North America (apart from in Michigan). Instead, the beet is harvested in a two-step process. First of all, the sugarbeet is defoliated in a separate step before being uprooted with six- or eight-row lifters. A widespread method is to load the beet directly onto trucks (which drive across the fields during harvesting), with good harvesting conditions essential.

Large harvest volumes, a brief window for the sugarbeet harvest and limited processing capacities necessitate more sophisticated storage technology than that usually found in Europe. In the United States, the beet is stored at specialist facilities, with clamps of up to 700,000 t formed. Professional clamp management is vital, with state-of-the-art sensor technology enabling specialist ventilation methods to keep the clamps cool. In turn, this maximises storage periods and minimises sugar loss.

Defoliation during the harvest of sugar beets

Defoliation during the harvest of sugar beets

Sugar beets harvesting site

Sugar beets harvesting site

Betaseed knowledge transfer offers insights into the processes, technologies and methods used to grow sugarbeet in North America. In China, we organise seminars for farmers and agricultural consultants on topics such as tillage and sugarbeet fertilisation. As such, Betaseed helps the Chinese agricultural sector boost the productivity of its sugar beet cultivation.

American storage technology takes centre stage in Russia and Ukraine

We organise visits to American sugar companies and put farmers in touch with experts. The first American-style storage systems are already in use in Russia, with Ukraine set to follow suit. In conjunction with local climatic conditions, the new storage technology will reduce storage-related sugar losses – and boost the productivity of sugar firms.